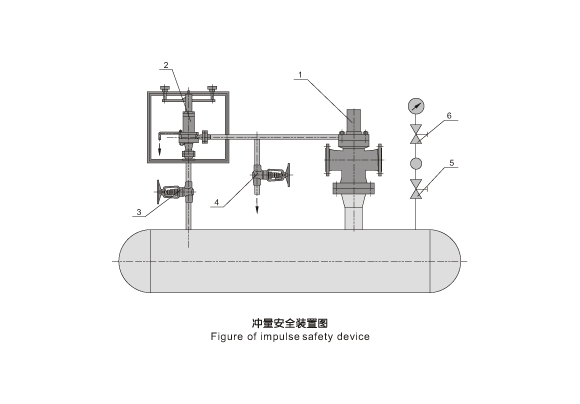

Description:

| 1.主安全阀 Main safety valve |

DN100; PW5414V |

| 2.冲量安全阀 Impulse sesafety valve |

DN20; PW5414V |

| 3.截止阀 Stop valve |

DN20; PW5417V |

| 4.节流阀 Throttle valve |

DN10; PN32 |

| 5.截止阀 Stop valve |

DN10; PW5417V |

| 6.三通阀 Triple valve |

DN4; PN32 |

Instruction

This device is used for power plant boilers with steam working conditions as: P=13.72MPa; t=540 Its main function is to avoid the medium pressure inside the boiler exceeding the allowable value to ensure that the boiler run safely.

Specialties:

The impulse scfety is installed with the main saftey valve.

This device has large discharge ability with convenient adjustment.

Operation principle:

When the medium pressure inside the boiler surpasses the al-

lowable value, the impulse safety valve opens firstly; the steam en- ters into the piston chamber of the main safety valve, forcing the main safety valve to open; the boiler bengins discharging steam; af- ter the excess pressure has been released, the impulse safety valve Closed, stopping the steam entering into the piston chamber of the main safety valve; the main safety valve automatically closes at the reactions of the springs and medium.

Structure briefing

1.The impulse safety device is as shown in the figure, mainly

consisted of impulse safety valve, main safety valve, stop valve and Throttle valve. Impulse safety valveis a kind of spring safety valve. It is mainly consisted of body, bonnet, spring, disc and other parts. The impulse safety valve can be adjusted by using the spring to regulate the pressure.

The impulse safety valve contains an electromanget to open and another to close the valve. The actions of the mechanism and the alectric appliance are separate and will not affect each other.

2.The main safety valve is as shown in the figure. With a sturcture of double exhaust, it is mainly consisted of body, cushion valve, psiston chamber, disc and other parts. The valve adopts the self tightening and sealed structure.

The higher the pressure of the medium is, the better the seal performance becomes. The cushion valve serves as a buffer in the working process of the master relief valve to avoid the damage of the sealed surface and the disc.

3.Both the seat and the sealed surface of the disc of the impulse safety valve are made of hard alloy of cobalt by overlaying welding. Both the seat and the sealed surface of the disc of the main safety valve are made of hard alloy of cobalt by plasma spray welding.

4.The upper part of the impulse safety valve contains an elec- tromagnet to open and another to close off. At ordinary times, the close-off electromagnet may not be electrified, but when the sealed surface of the valve leaks, it can be electrified over a long period of time to make the valve sealed. Or when the mechanical adjusting reseating pressure is excessively low, it can be electrified to help the disc return and procure a higher reseating pressure.

5.The impulse safety valve only leaves the factory after it has

Passed the seal and sensitivity tests.

Installation instruction:

1.The main safety valve, A49Y-Pw5414V, DN100, and the impulse

safety valve, A49 Y-Pw 54 10V, DN20, should be installed together, The sistance between the outlet pipe of the impulse safety valve and the inlet pipe of the main safety valve should be maintained as rela- tively long and the distance between the electric contact pressure meter and the inlet pipe of the main safety valve should be no less than 5 times of the diameter of the inlet pipe, for fear that the pre- cision of the meter and the impulse safety valve may be affected by the steam discharging process of the main safety valve.

2.Before the installation of the impulse safety valve, the pipeline shall be cleaned first.

3.The main safety valve and the impulse safety valve must be positioned vertically. After the installation and the welding of the main safety valve, it shall be under partial heat treatment.

4.The main safety valve shall be fastened upon the framework, which sustains the counter-reaction force produced in the steam discharging process of the main safety valve. The exhaust pipe of the main safety valve shall be supported with a special gallow lest the force of its weight and action would be directly apply to both the main safety valve and the flange that is connecting them. At

the lowest point of the exhaust pipe, water drainage shall be taken into consideration to avoid producing water hammer when the main safety valve is discharging steam. The three loops of filling shall be deeply comperssed until the lower surface of the filling gland touch-

es the upper surface of the piston, and a fine wire shall be used to fasten the pressure bolt to avoid leakage and refusing release of the main safety valve.

5.The impulse safety valve and the electromagnets shall be placed together on a special gallow. The juncture of the upper lever of the valve and the electromagents shall be flexible, with no phe- nomenon of seizure. The impulse safety valve shall be installed in a place with little dust, dry air and convenient maintenance and de- bugging, and where no vibration occurs. Its ambient temperature

Shall not higher than 70 , and its relative humidity not more than 80%.

6.To ensure the agile working of the impulse safety valve, the distance between the circular arc part of the head of the seat re- rurning lever and the end of the pressure bar of the valve shall be adjusted to the length of the actual travel of the valve adding 1 mm

(adjusted by the M10 fastening screw at the top of the cap).

产品名称:超高压冲量安全装置(H系列) A49Y

产品名称:超高压冲量安全装置(H系列) A49Y